Effective commercial electrical maintenance is crucial for the smooth operation of businesses, ensuring safety, compliance with regulations, and minimizing costly downtime. In this article, we will explore essential tips for maintaining commercial electrical systems, providing guidance on creating a maintenance schedule, conducting routine inspections, addressing potential hazards, performing preventive maintenance, and the benefits of hiring professional electrical services.

Understanding Commercial Electrical Systems:

Commercial electrical systems are complex networks comprising various components and equipment. These systems power critical operations such as lighting, HVAC, machinery, and computer systems. Understanding the components and challenges associated with commercial electrical systems is essential for effective maintenance.

Importance of Regular Maintenance:

Regular maintenance offers numerous benefits, starting with ensuring safety and compliance. It helps identify and rectify potential hazards before they cause accidents or damage to property. Maintenance also enhances energy efficiency, reducing operational costs. By performing preventive tasks and inspections, the lifespan of electrical equipment can be extended, avoiding the need for costly repairs or premature replacements.

Essential Tips for Effective Commercial Electrical Maintenance:

Create a Maintenance Schedule:

Establish a comprehensive maintenance schedule that outlines the frequency of inspections and necessary maintenance tasks. Regularly review and update the schedule based on the specific needs of your facility. Additionally, maintain detailed documentation and records of all maintenance activities for reference and compliance purposes.

Conduct Routine Inspections:

Regular inspections are vital for identifying potential issues and addressing them promptly. Inspect electrical panels and circuit breakers for signs of wear, loose connections, or overheating. Examine wiring and connections, looking for signs of damage, fraying, or corrosion. Evaluate lighting systems to ensure proper functionality, and test emergency backup systems to guarantee they are fully operational.

Address Potential Hazards:

Identify and address potential electrical hazards promptly to mitigate risks. Ensure all electrical equipment and wiring are properly grounded. Maintain adequate clearance around electrical panels and equipment to prevent overheating. Implement proper signage to indicate hazardous areas and provide appropriate personal protective equipment (PPE) for employees working near electrical equipment.

Regularly Clean Electrical Equipment:

Dust and debris accumulation can compromise the performance and safety of electrical equipment. Regularly clean electrical panels, machinery, and other components using approved methods. Clear air vents and cooling systems to prevent overheating, as this can lead to equipment failure or fire hazards. Take note of any signs of overheating, such as unusual smells or discoloration.

Perform Preventive Maintenance Tasks:

Engage in preventive maintenance tasks to prevent unexpected failures and breakdowns. Tighten loose connections regularly to prevent overheating and ensure proper electrical flow. Lubricate moving parts to reduce friction and extend equipment lifespan. Replace worn-out components, such as faulty switches or damaged cables, promptly. Regularly test and calibrate electrical measuring instruments for accurate readings.

Train and Educate Staff:

Proper training and education are crucial for maintaining a safe and efficient electrical environment. Provide electrical safety training for all employees, emphasizing the importance of adhering to safety protocols and reporting any electrical issues. Educate staff on recognizing warning signs of electrical problems, such as flickering lights or burning smells. Establish clear communication protocols for reporting and addressing electrical concerns promptly.

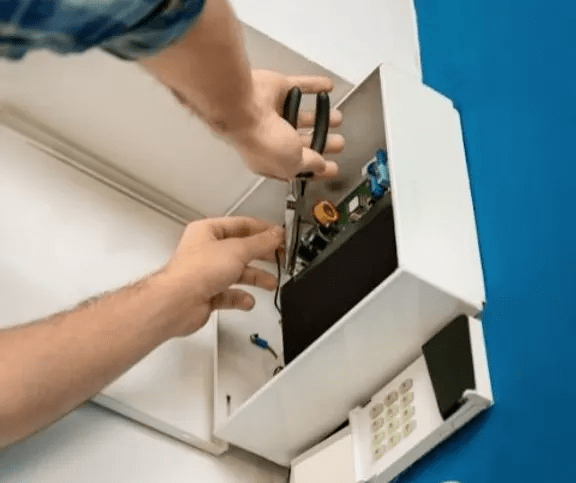

Hiring Professional Electrical Services:

While some maintenance tasks can be performed in-house, hiring professional electrical services has its advantages. Professionals possess the expertise and experience to handle complex electrical systems and can provide valuable insights and recommendations. When selecting an electrical contractor, ensure they are qualified, licensed, and have a track record of successful commercial maintenance projects. Maintain open communication and collaboration with the service provider to ensure efficient maintenance operations.

Conclusion:

Effective commercial electrical maintenance is essential for safety, compliance, and operational efficiency. By following the outlined tips, businesses can minimize risks, extend equipment lifespan, reduce downtime, and optimize energy consumption. Regular inspections, addressing potential hazards, performing preventive maintenance, and partnering with professional electrical services contribute to a secure and productive electrical environment. Implement these tips to safeguard your business, maintain compliance, and achieve optimal performance from your commercial electrical systems.